MISSION CRITICAL

MISSION COMFORTABLE

See why we’re the global leader in

control consoles and furniture

WINSTED DESIGNS MISSION CRITICAL CONTROL ROOM CONSOLES AND TECHNICAL FURNITURE

Clearing a path to productivity. A path to win. It’s right there in our name. And the result of our commitment to creating freedom — freedom to focus, to think, to succeed. Sit/stand continuous use technical desks. A furniture system of intelligent ergonomics to become an extension of body and mind. Seamless integration. Impeccable detail. Inspired design. A higher functioning form and function. Our mission is to engineer the environments where design meets detail and comfort creates control.

Meeting all ISO and OSHA guidelines. Exceeding all expectations.

Mission accomplished.

Contact Winsted

"*" indicates required fields

WE REDEFINED OUR INDUSTRY.

AND NOW OURSELVES.

Our new line is at the head of the line.

DESIGN ASSISTANCE

Our experienced Control Room Design Team is ready to convert your ideas and technical furniture requirements into a finished solution to meet your mission-critical needs. Click here to connect with us today.

WORLD LEADER IN

CONTROL ROOM CONSOLES

Our experts combine the disciplines of industrial design, ergonomics, and interior design to create control room solutions that are both efficient and eye-catching. We give special consideration to the ergonomic requirements of your operators to build consoles that reduce fatigue, improve productivity and inspire. Click on the images below to see some examples of actual installations.

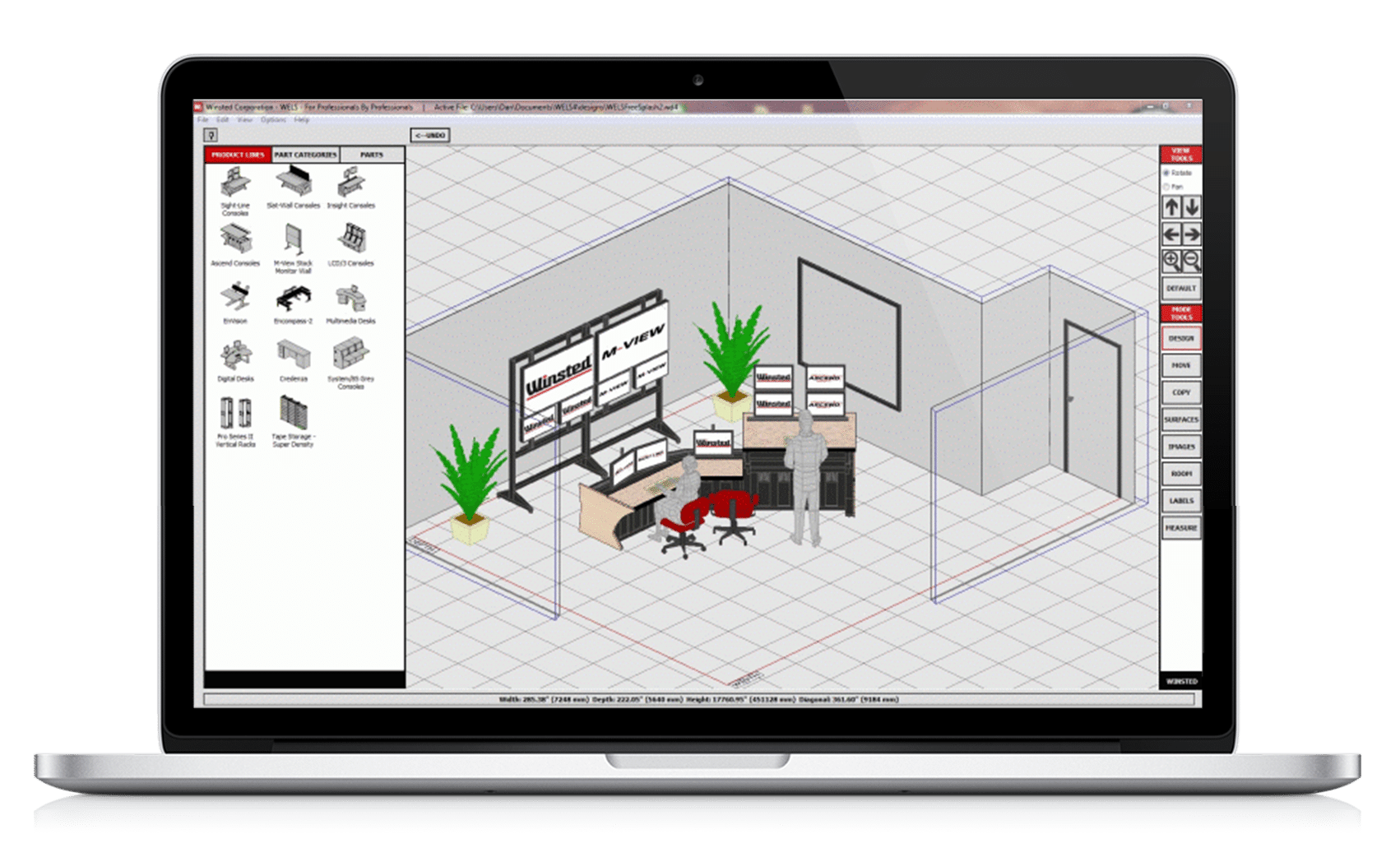

WELS 4

POINT.CLICK.DONE

The MOST ADVANCED console design software is here! WELS is a console design software tool that makes control room design and layout fast, easy, accurate and fun! This interactive, Winsted-exclusive, user-friendly, 3D control room design software program lets you use Winsted consoles and furniture to quickly design control room solutions that meet your needs. WELS is easy to use and requires no additional design/CAD software to operate.

A NEW VUE FROM WINSTED